Sample test example for plastic sorting by - Quattro sensors prism spectroscopic linescan camera - Part 6

Sample test example fore plastic sorting by BVC6200 (R, G, B, swir) using BVC6100 or BVC6200 - Quattro sensors prism spectroscopic linescan camera - Part 6.

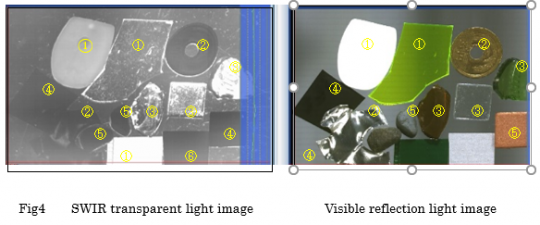

Fig. 4 shows several different materials of captured image taken by reflection visible light and transparent SWIR light.

The sample materials used in fig. 4 are:

- Plastic

- Metal

- Glass

- Tile

- Stone

- Paper

It is hard to figure out plastic by a Visible Reflection light image only, however it is more easy to detect plastic by comparing both a Visible light image ánd SWIR transparent light image. As SWIR transparent light is not able to go through non-plastic materials (like tile, stone, paper, metal), those objects should be black coloured in the image, but not the plastic. So you have created an efficient way of sorting in this way.

More about customized filters?

#Spectroscopic #Semiconductor #Industrial Imaging #Spectroscopic imaging #Prism #Organic #Sorting #Quality #Safety

1.1 bluevision Japan

We are specialists in the niche market developing spectroscopic cameras at customer request. Small demands of camera units fit our strategy as we have a flexible production which is utilized for small series. Depending multispectral on volume request NRE cost may apply.

Our goal is to be a company always pursuing innovation that helps improvement of productivity in the industrial field by our cutting-edge technology of Prism Spectroscopic Imaging (PSI).

In 2021 we reached the number of more than 20.000 lenses produced by BlueVision. On top we have designed more than 40 different camera types in the last 10 years. We are able to do this since we understand the bridge multispectral between 'Legacy technology, Japanese workmanship & the Newest sensor Spectroscopic imaging technology.

Click here for the catalogue of our products

1.2 Mission Strategy bluevision Europe (BLVE)

For two years Bluevision management decided to expand by a local presence in Europe. Similar to other important markets, Bluevision believes it is important to be with its customers in the same time zone. The mission is to build the brand visibility in Europe and supporting its partners and OEM customers in what they need within their planning.

1.3 Spectroscopic imaging

Spectroscopic Imaging starts with Japanese workmanship to mount the newest high technology sensors to the prism bonding by a 6 axis alignment tool in the clean room. The process of creating the prism molecular is of course in a clean room (ISO 6; class 1.000). The production facility to mount the sensors to the prism, facilitates multiple 6 axes prism stations.

Due to our experience of high-end surveillance camera electronics, our products do meet high standards and can be used in harsh environment like farming conditions. High humidity and temperatures do fit in our design philosophy. Our products are tested in climate chambers (for shock and vibration). Click here for more information on spectroscopic imaging

1.4 Multispectral

Multispectral with using prism is the best method of combining wavelenghts of different frequencies: https://en.wikipedia.org/wiki/Spectroscopy >>https://en.wikipedia.org/wiki/Spectroscopy.